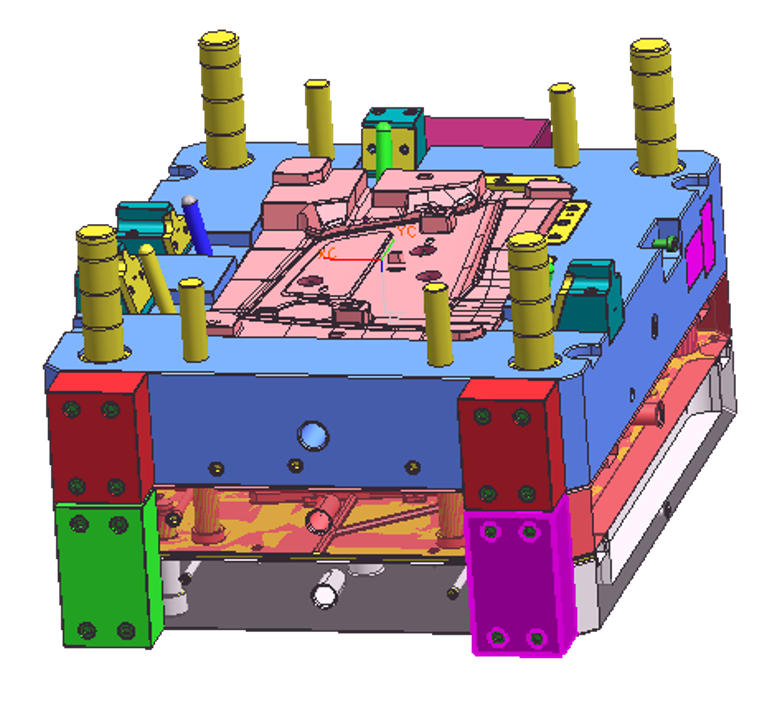

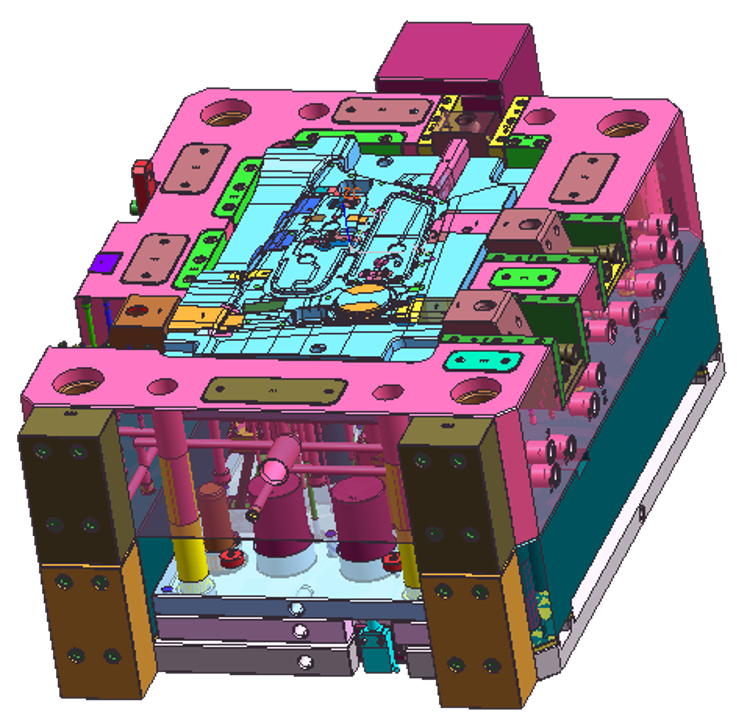

Kim Dai has built a strong design team, familiar with the DME and Hasco standards, that processes from the part design to mold design. During the design stage, Kim Dai's design team can ensure the fastest productivity and most efficient communication.

We have 2 R&D Centers combined with 20 engineers which take the work from part design to mold design, Including the service for part design, prototyping, reverse engineering, mold flow analysis, DFM and mold 2D & 3D design. Our mold design capacity includes the mold types as below:

hot/cold runner injection moulds

hot/cold runner injection moulds

multi-cavity injection moulds (up to 64 cavities)

big size mould (Up 20 Ton)

stack mould

2-Shots mould

over-mould, insert-mould

unscrewing mold, prototyping mold

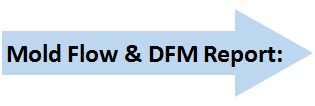

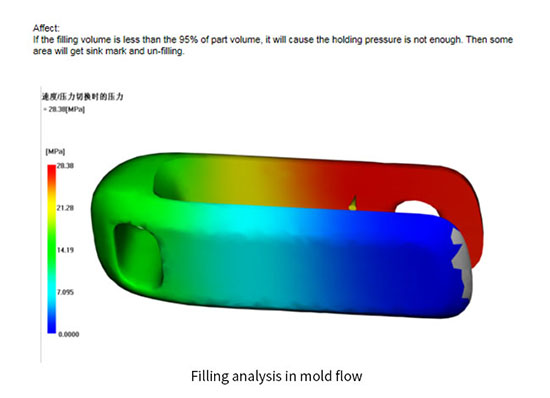

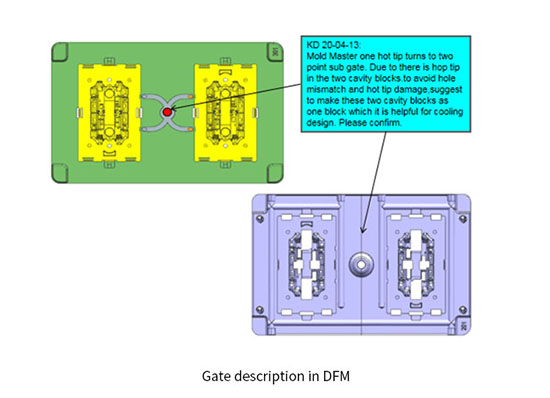

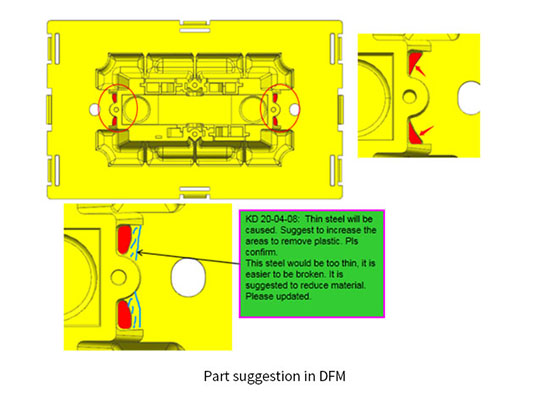

Before any mold project starts, we would do the preliminary part structure analysis and demoulding virtual analysis. Based on our knowledge of the design, we can guarantee that the project can proceed safely and smoothly. Normally, the DFM report would include information such as gate type and location, part structure suggestion, molding injection movement, cooling design, part surface treatment, sink mark description, ejector type and system, engraving information, etc. And mold flow would describe the filling pressure, time etc.

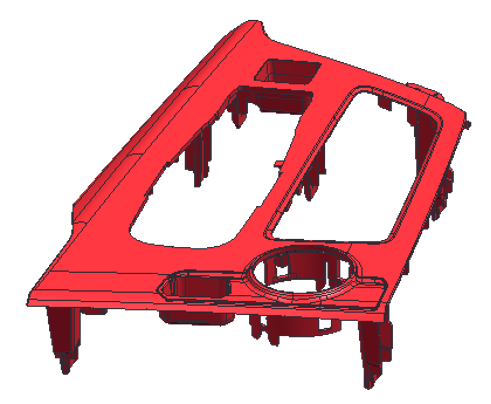

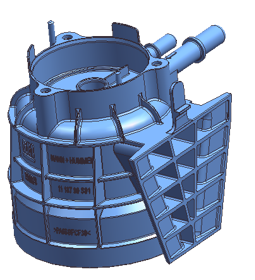

Case 1:

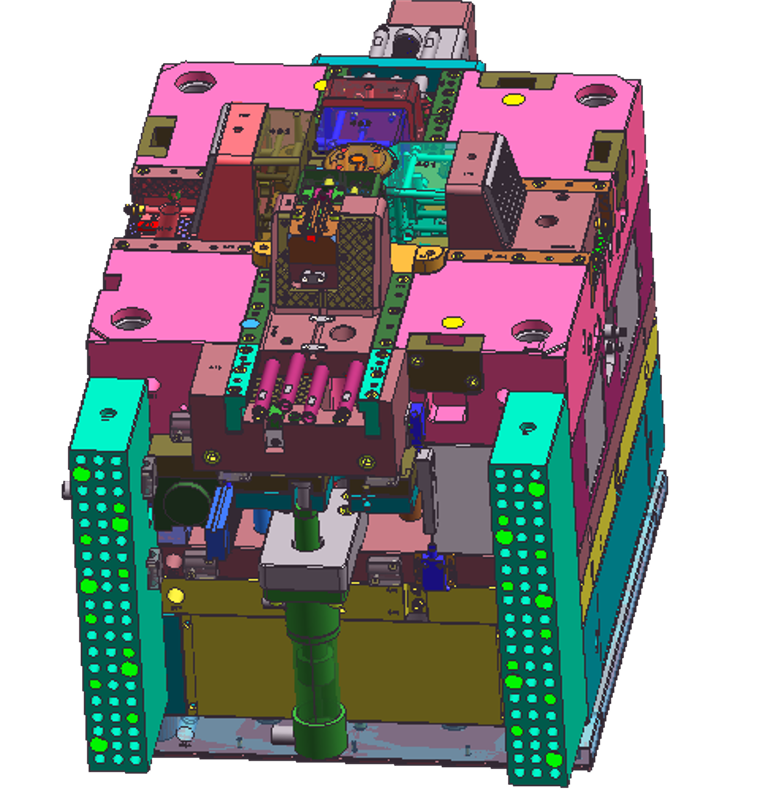

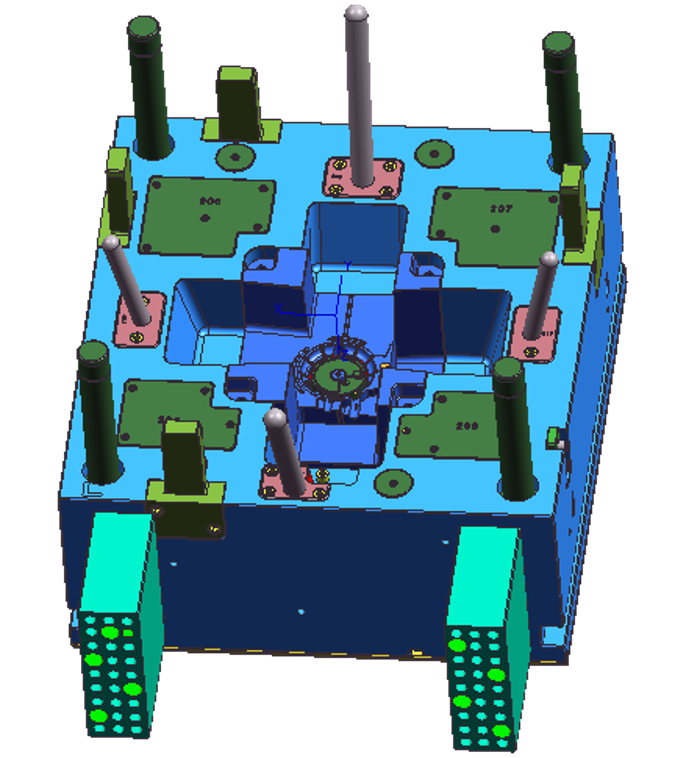

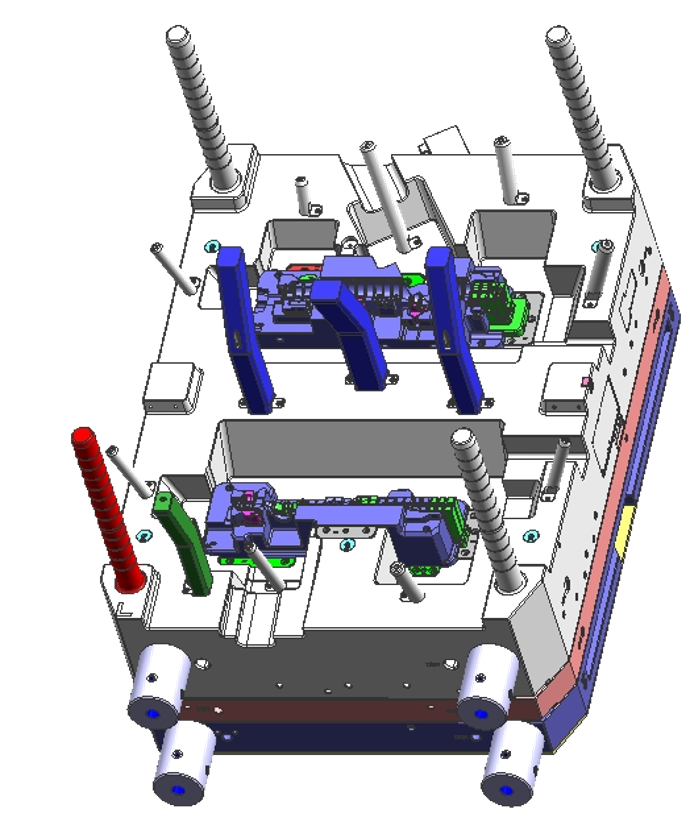

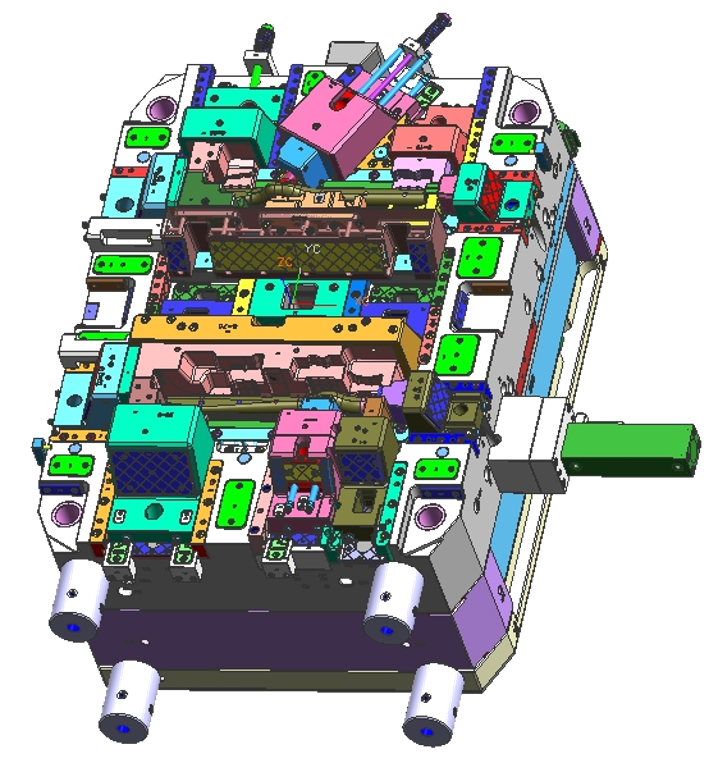

Case 2:

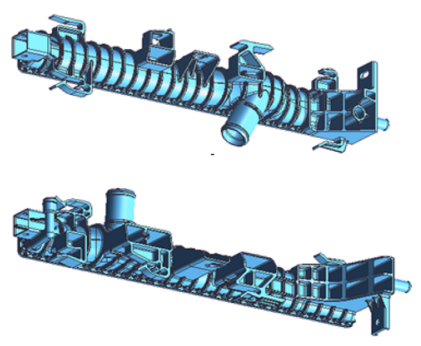

Case 3: